Introduction to Milling Machine Processing Technology

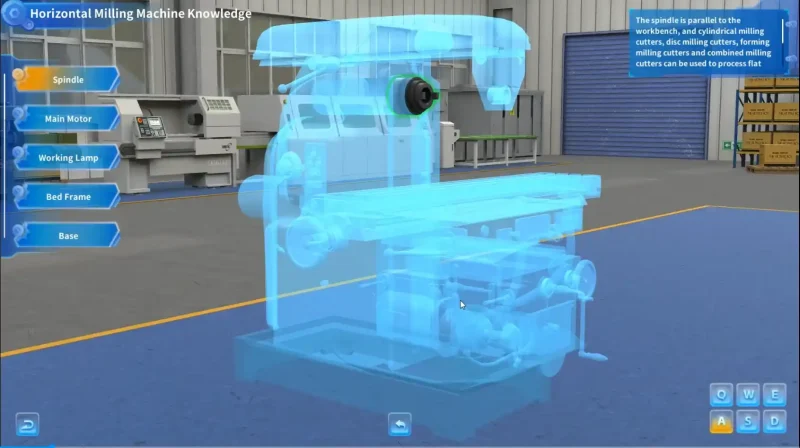

The Milling Machine Processing Technology Simulation Training System is a cutting-edge educational tool designed to revolutionize the way students and professionals engage with milling machine operations. Leveraging Virtual Reality (VR) technology, this software allows users to interact with highly detailed, proportional models based on actual milling machines. These virtual simulations mirror the operations of horizontal universal lifting milling machines and vertical lifting table milling machines, making it possible to gain practical experience without the constraints of time, space, or location.

Whether you’re in a classroom, training center, or even remotely, this system offers a realistic 360-degree virtual environment, providing users with a comprehensive understanding of milling machine operations through engaging and intuitive learning methods.

Key Features and Benefits

-

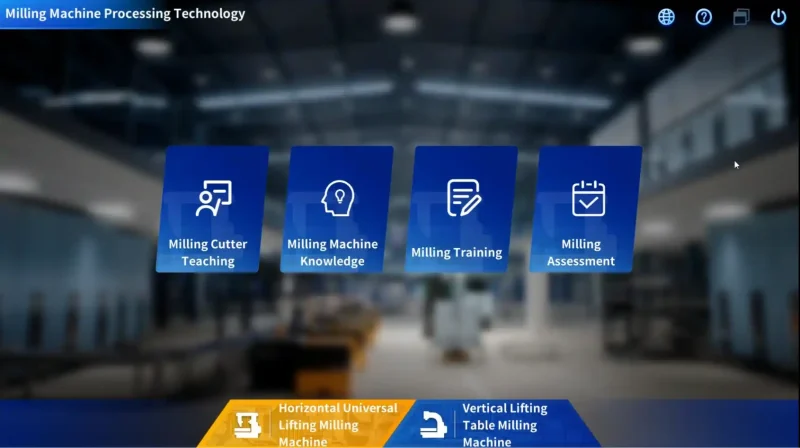

Versatile Milling Machine Simulations The system simulates both horizontal universal lifting milling machines and vertical lifting table milling machines, covering a wide range of milling techniques and operations, making it suitable for diverse training needs.

-

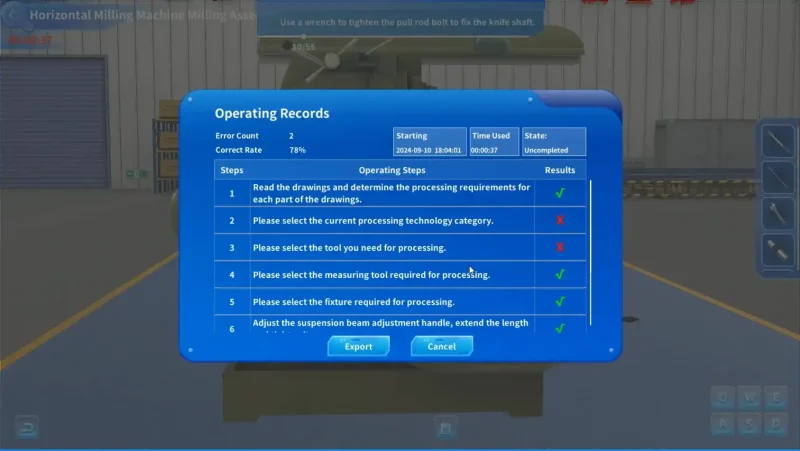

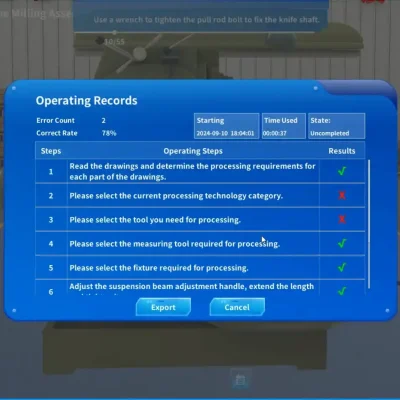

Interactive Training Modes With two distinct modes, “Practical Training” and “Assessment,” users can progress from basic operations to more complex tasks. These modes help enhance understanding and ensure the learner’s readiness for real-world applications.

-

Comprehensive Learning Modules The software offers four essential learning modules: Milling Cutter Teaching, Milling Machine Cognition, Milling Training, and Milling Assessment. These modules provide a well-rounded approach to milling machine education, from basic theory to hands-on practice and assessment.

-

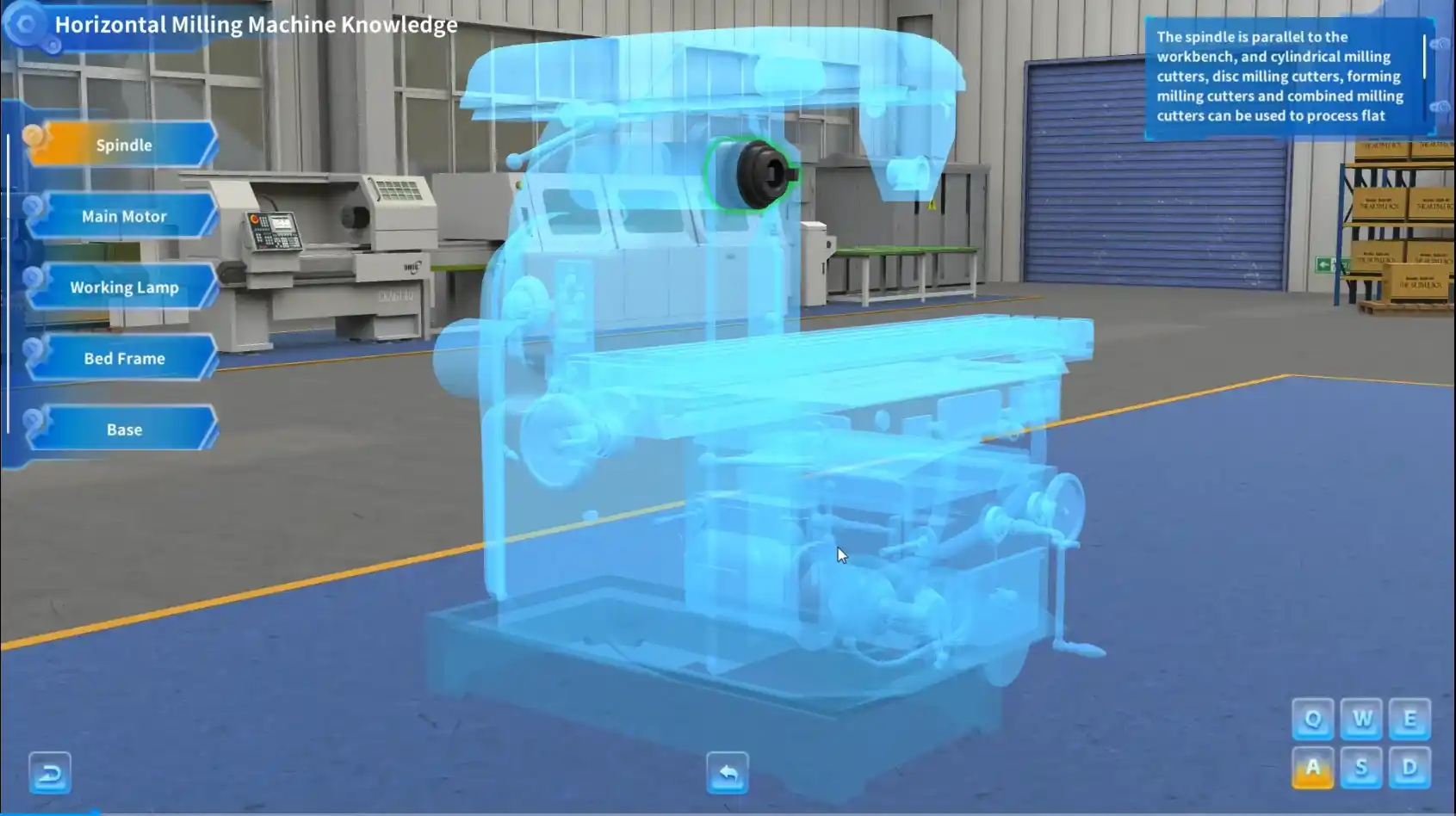

Real-World Simulation By simulating the standard milling machine operations, users gain an authentic learning experience without the risks associated with physical training. The software allows for full interaction with the virtual models, including rotating, zooming, and surrounding views to analyze different components in detail.

-

Time and Space Flexibility Users are no longer restricted by the limitations of traditional physical training. The system allows for continuous access to the virtual training environment, making it easier for instructors and students to engage in repeated learning without time constraints.

-

Safety and Risk Management The simulation offers a high level of safety by avoiding the risks of actual milling machine operations, especially for beginners or those practicing complex tasks. This is ideal for schools and training centers that prioritize a safe learning environment.

-

Adaptability for Multiple Platforms The software is designed to work seamlessly with various devices, including all-in-one machines and PCs, ensuring accessibility and ease of use in different training setups.

Application Areas

-

Academic Fields: Ideal for mechanical design and manufacturing programs, providing students with practical insights into milling machine operations, mechanical drawing, and machine tool operation.

-

Relevant Professions: This training system is tailored for aspiring machine tool milling workers, mechanical design engineers, and those looking to enhance their skills in machining and milling operations.

-

Educational Institutions: Perfect for use in universities, vocational schools, and training centers, providing a modern approach to hands-on learning.

Core Functionalities

-

Cognitive Learning: Users can learn the fundamentals of milling machine operation and gain knowledge of milling processes.

-

Training Simulations: Engage in practical training exercises that simulate the exact steps and processes of milling operations, enhancing technical skills in a controlled, risk-free environment.

-

Assessment and Progress Tracking: The system features an assessment mode that helps instructors track student progress and ensure readiness for real-world milling tasks.

Conclusion: Empowering the Future of Milling Machine Training

The Milling Machine Processing Technology Simulation Training System by Richter is a groundbreaking solution for teaching and training in mechanical design and manufacturing. Its innovative use of VR technology, coupled with a detailed simulation of real-world milling machines, ensures that both students and professionals can gain the practical experience they need to succeed. This software is a vital tool for educational institutions looking to provide high-quality, safe, and accessible training on milling machines.

For institutions and training centers, this system offers a flexible, engaging, and effective way to teach milling machine operations, bridging the gap between theoretical knowledge and hands-on expertise.