Advanced Training for Precision Grinding Skills

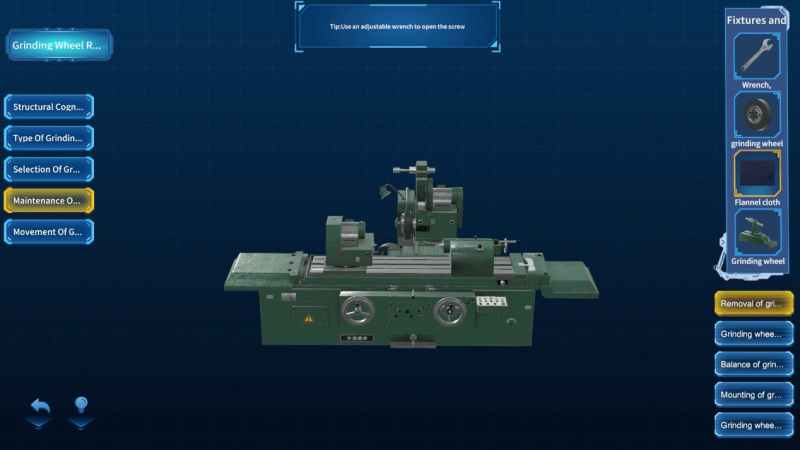

At Richter, we understand the importance of hands-on experience in mastering the complex processes of grinding technology. Our Virtual Simulation Teaching System of Grinding Technology is an innovative educational platform designed to help students gain proficiency in precision grinding techniques. Ideal for educational institutions and training centers, this system combines advanced virtual reality (VR) simulations and interactive learning modules to provide a risk-free, immersive training environment.

Product Features

-

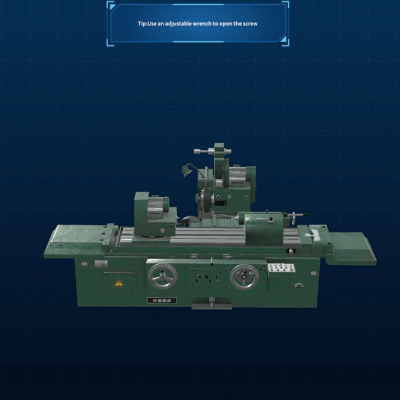

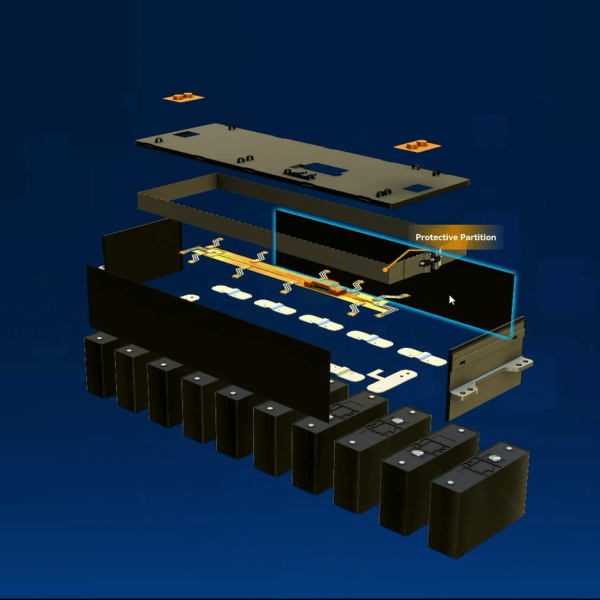

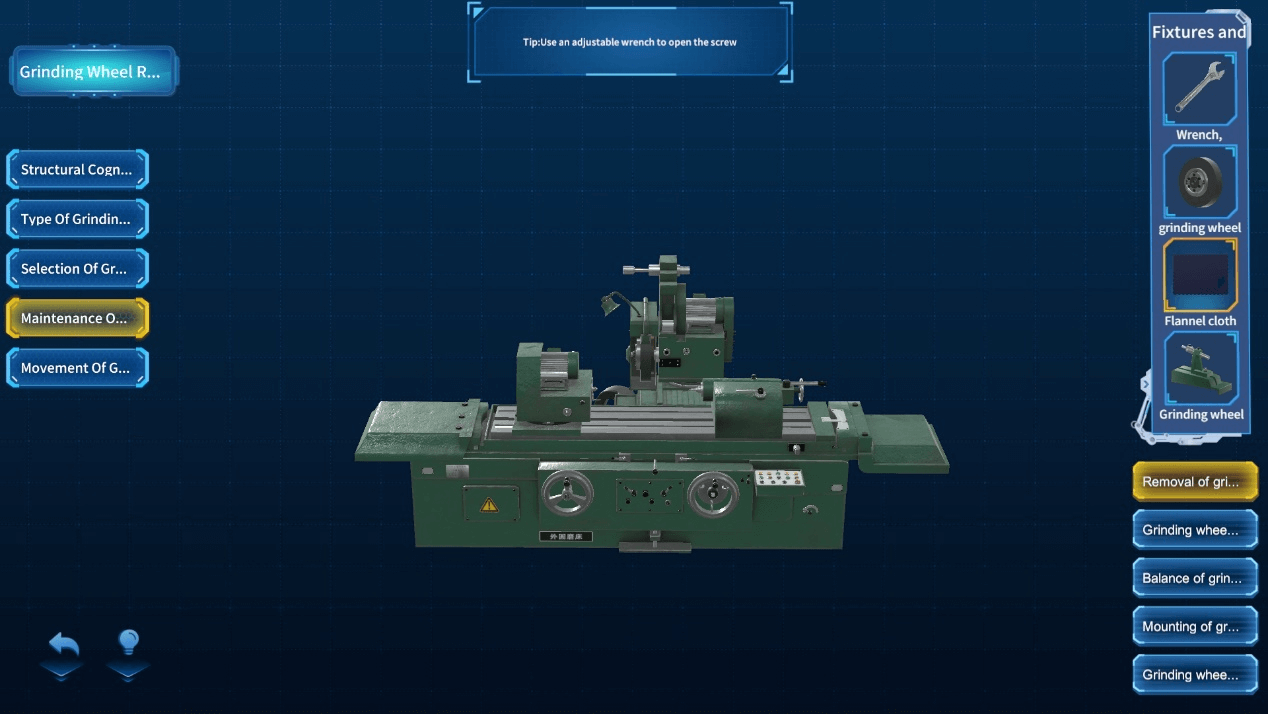

Interactive 3D Virtual Simulations

Dive into a highly realistic 3D environment, where students can interact with various grinding machines, tools, and components. The system simulates the grinding process with remarkable accuracy, replicating real-world material behavior and machine dynamics. -

Core Grinding Modules

The system is divided into two key modes: Practical Training Mode and Assessment Mode, each covering vital aspects of grinding operations.Practical Training Mode includes:

- Grinding Wheel Recognition: Learn to identify different types of grinding wheels, such as abrasive grains and bond types.

- Fixture and Gauge Recognition: Understand the role of workholding devices and precision measurement tools used for dimensional accuracy.

- Grinding Methods: Master essential grinding techniques, including surface grinding, cylindrical grinding, and centerless grinding.

- Machine Awareness: Gain familiarity with the operations of external cylindrical grinders, internal cylindrical grinders, and planar grinders.

- Real-Time Interaction: Explore different types of grinders and observe the effects of operational adjustments in real time.

Assessment Mode includes:

- Conical, Tubular, and Prismatic Parts Assessments: Evaluate and test skills in producing different geometries with precision.

- Step-by-Step Interactive Simulations: Receive detailed guidance while performing complex tasks, helping students develop technical expertise.

-

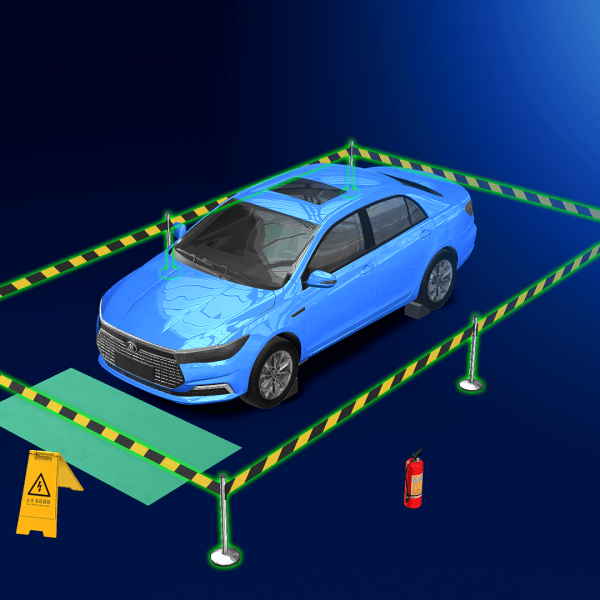

Safety Protocols and Risk Simulations

Our system integrates virtual risk simulations, such as wheel breakage or improper clamping, to train students on safe handling practices. Safety protocols are embedded throughout each operation, ensuring compliance and minimizing the risk of accidents. -

Customizable Learning Experience

Whether students need flexible, self-paced practice or structured assessments, our system offers both options. It allows for adaptable learning paths based on individual progress and skill level. -

Data-Driven Feedback

The system generates detailed performance reports, allowing students to track their progress over time and identify areas that need improvement. Immediate error correction is provided through visual alerts and corrective feedback to reinforce learning. -

Cross-Platform Accessibility

The system can be accessed on PC or via VR headsets, providing students with the flexibility to train anytime, anywhere, making it suitable for both in-class and remote learning.

Value for Students

The Virtual Simulation Teaching System of Grinding Technology offers unparalleled hands-on training without the risks associated with physical machinery. Students can:

- Gain practical experience with grinding operations in a virtual environment.

- Understand the intricacies of different grinding wheels, fixtures, and gauges.

- Simulate various grinding methods, including cylindrical and surface grinding, with real-time interaction.

- Assess and refine their skills with customizable assessments focused on complex geometries.

- Build confidence with risk-free practice, preparing them for real-world scenarios.

Value for Instructors

Instructors benefit from the Virtual Simulation Teaching System of Grinding Technology by having an easy-to-use, advanced teaching tool at their disposal:

- Demonstrate grinding technology in a risk-free, controlled virtual environment.

- Use the system’s detailed simulations and assessments to provide students with practical experience and measurable results.

- Quickly assess student performance and tailor lessons based on individual needs.

- Promote collaborative learning by allowing multiple students to interact with the system simultaneously.

- Save time on setup and maintenance compared to physical grinding equipment, making classroom management more efficient.

Key Specifications

- Software Type: Virtual Simulation Teaching System

- Technology: VR Integration with 3D Interactive Models

- Training Modes: Practical Training Mode, Assessment Mode

- Customizable Assessments: Conical, Tubular, and Prismatic Parts

- Platform Compatibility: PC and VR Headsets

- Real-Time Feedback: Immediate Error Correction, Data-Driven Reports

- Safety Compliance: Embedded Safety Protocols for Risk Simulations

Conclusion

Richter’s Virtual Simulation Teaching System of Grinding Technology revolutionizes the way grinding technology is taught, providing students with a comprehensive, immersive learning experience. By offering realistic simulations, customizable learning paths, and detailed performance analysis, this system ensures that students are well-prepared for the challenges of modern precision grinding.

Enhance your training programs today with our cutting-edge virtual simulation software, and help students develop the skills they need to succeed in the competitive field of manufacturing.

For more information about this product or other innovative training solutions from Richter, visit our website or contact our sales team.